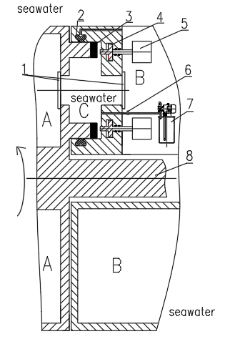

Underwater Access Door System for Tidal Power Generation

Abstract

The difficulty in maintaining tidal power generation equipment is an important factor restricting its development. The tidal power underwater access door system uses a power device to drive the metal seal. When the machine is stopped, a temporary channel is formed between the rotating and stationary parts. After drainage, personnel can maintain the rotating parts through the channel. In the past four years of use, the system has good stability and zero leakage, solving the problem of having to pull out of the sea for maintenance of tidal power generation equipment and reducing maintenance costs.

References

[2] Lv, X., & Guo, P. (2011). Review of China's tidal energy development. Transactions of Oceanology and Limnology, (1), 26–30.

[3] Douglas, C. A., Harrison, G. P., & Chick, J. P. (2008). Life cycle assessment of the Sengen marine current turbine. Engineering for the Maritime Environment, 222(1), 1–12. https://doi.org/10.1243/14750902JEME94

[4] Fraenkel, P. L. (2002). Power from marine currents. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 216(A1), 1–14. https://doi.org/10.1243/095765002760024782

[5] Yu, Y., Gai, F., Ding, Y., & Yu, L. (2020). Compliance calculation and analysis for an S-type cantilever beam. Journal of Vibration and Shock, 39(3), 276–281.

[6] Wang, D., Qiang, Q., Xia, C., & et al. (2023). Tribocorrosion behavior of FH36 steel in simulated seawater with different salinity. Tribology, 43(1), 64–72.

[7] Huang, J., Cao, J., Wang, J., Zhang, L., & Zhao, C. (2019). Effect of pre-strain on electrochemical corrosion of X100 pipeline steel. Shipbuilding of China, 60(3), 203–208.

[8] Yan, S. (2024). Research progress on hydrogel marine antifouling materials. Applied Chemical Industry, 53(4), 906–910.

[9] Chen, X., Tang, M., Liu, Q., & et al. (2017). The research progress in the attachment of barnacles. Marine Sciences, 41(7), 150–156.

[10] Luo, Y., Song, S., Jin, W., & et al. (2008). In field electrochemical detections and corrosion behavior of carbon steel samples. Journal of Chemical Industry and Engineering (China), 59(11), 2865–2869.

[11] Li, J., Wang, Z., Chen, L., & Liang, H. (2016). Research progress of anti-fouling coatings in hydraulic engineering. Journal of Yangtze River Scientific Research Institute, 33(4), 125–130.

[12] Gong, Z., Zhang, L., Cheng, L., & et al. (2019). High temperature seawater corrosion behavior of high strength steel for marine flexible pipe. Transactions of Materials and Heat Treatment, 40(5), 89–95.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright for this article is retained by the author(s), with first publication rights granted to the journal.

This is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).