Optimization of Condensate Transfer Pump in the Hydrocarbon Condensate Stabilization Unit of Natural Gas Liquefaction Plant – An Industrial Case

Abstract

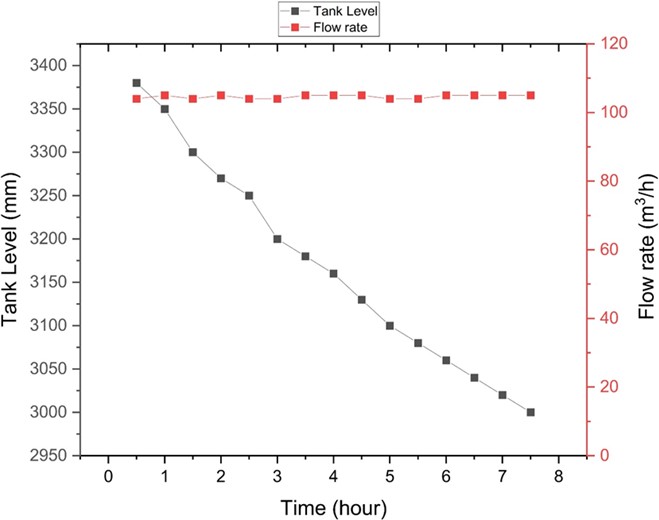

PT. Badak NGL is a commercial LNG producer located in Bontang, Indonesia. In recent years, the decline in LNG production of PT. Badak NGL results in a lower hydrocarbon condensate flow rate. To prevent power losses since its pump operated at below rating, a new operation scheme was proposed. This new scheme adjusts the way of pump is operated without any alteration in terms of pump characteristics. Three pumps operated intermittently for 8 hours per day at a maximum flow rate. The pump power consumption was calculated based on electric current data monitored by relay panel. The results show that the pump energy saved by 60% with the absolute value of annual energy efficiency of 957.7 MWh. This study contributes to reducing the greenhouse effect by 412 tons eq CO and the annual production cost of around USD 130,000. The new scheme reliability examines by evaluating pump vibration, pump performance, hydrocarbon condensate quality, and condensate tank liquid level. The result shows that the pump’s vibration in the range of 0.21 in/sec with a steady winding temperature.

References

Fiaschi, D., Graniglia, R., & Manfrida, G. (2005). Improving the effectiveness of solar pumping systems by using modular centrifugal pumps with variable rotational speed. Solar Energy, 79(3), 234-244. https://doi.org/10.1016/j.solener.2004.11.005

Gopal, C., Mohanraj, M., Chandramohan, P., & Chandrasekar, P. (2013). Renewable energy source water pumping systems—A literature review. Renewable and Sustainable Energy Reviews, 25, 351-370. https://doi.org/10.1016/j.rser.2013.04.012

He, T., & Ju, Y. (2016). Dynamic simulation of mixed refrigerant process for small-scale LNG plant in skid mount packages. Energy, 97, 350-358. https://doi.org/10.1016/j.energy.2016.01.001

He, T., Karimi, I. A., & Ju, Y. (2018). Review on the design and optimization of natural gas liquefaction processes for onshore and offshore applications. Chemical Engineering Research and Design, 132, 89-114. https://doi.org/10.1016/j.cherd.2018.01.002

Khan, M. S., & Lee, M. (2013). Design optimization of single mixed refrigerant natural gas liquefaction process using the particle swarm paradigm with nonlinear constraints. Energy, 49, 146-155. https://doi.org/10.1016/j.energy.2012.11.028

Kumar, S., Kwon, H.-T., Choi, K.-H., Lim, W., Cho, J. H., Tak, K., & Moon, I. (2011). LNG: An eco-friendly cryogenic fuel for sustainable development. Applied Energy, 88(12), 4264-4273. https://doi.org/10.1016/j.apenergy.2011.06.035

NEMA. (2009). NEMA MG-1: Motors and Generators.

Odeh, I., Yohanis, Y. G., & Norton, B. (2006). Influence of pumping head, insolation and PV array size on PV water pumping system performance. Solar Energy, 80(1), 51-64. https://doi.org/10.1016/j.solener.2005.07.009

Qu, D., Luo, W., Liu, Y., Fu, B., Zhou, Y., & Zhang, F. (2019). Simulation and experimental study on the pump efficiency improvement of continuously variable transmission. Mechanism and Machine Theory, 131, 137-151. https://doi.org/10.1016/j.mechmachtheory.2018.09.014

Rahmanian, N., Ilias, I. B., & Nasrifar, K. (2015). Process simulation and assessment of a back-up condensate stabilization unit. Journal of Natural Gas Science and Engineering, 26, 730-736. https://doi.org/10.1016/j.jngse.2015.06.058

Sun, H., He Ding, D., He, M., & Shoujun Sun, S. (2016). Simulation and optimisation of AP-X process in a large-scale LNG plant. Journal of Natural Gas Science and Engineering, 32, 380-389. https://doi.org/10.1016/j.jngse.2016.04.039

Vatani, A., Mehrpooya, M., & Palizdar, A. (2014). Energy and exergy analyses of five conventiliquefied natural gas processes. International Journal of Energy Research. https://doi.org/10.1002/er.3193

Wang, M., Zhang, J., & Xu, Q. (2012). Optimal design and operation of a C3MR refrigeration system for natural gas liquefaction. Computers & Chemical Engineering, 39, 84-95. https://doi.org/10.1016/j.compchemeng.2011.12.003

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright for this article is retained by the author(s), with first publication rights granted to the journal.

This is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

1.png)